Webinar “Demand forecasting in time of Covid-19”

21 May 2020Outliers impact on safety stock levels

25 May 2020

Webinar “Demand forecasting in time of Covid-19”

21 May 2020Outliers impact on safety stock levels

25 May 2020Impact of outliers (Outliers) on safety stock calculations

In the Japanese art of samurai sword fighting, iaidō, in addition to excellent technique, keeping alert and being able to act with lightning speed is very important. One of my favorite techniques is Ushirogiri. Our opponent is behind us. Until we turn around and analyze the situation, we cannot make an effective cut. The same is true of the Outliers. We won’t be able to make an accurate prediction if we don’t first turn back and capture Outliers in the sales history.

Outliers are unusual events that we face in our daily business practice. Abnormal events are most often understood as:

- One-off large sales resulting from unusual customer orders

- Sales

- Sales shortfalls resulting from out-of-stock situations

- External circumstances, such as the top-down introduction of trade restrictions

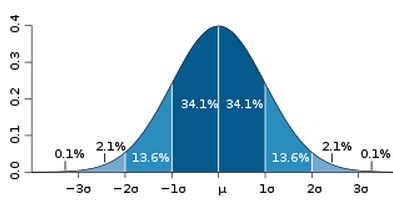

Failure to eliminate the impact of such phenomena in sales history has its consequences. The main one is the lack of a normal distribution of demand and thus high values of standard deviations.

Normal distribution

According to the classical theory of statistical safety stock management, its size depends on the standard deviation of demand and on our business goal, usually defined by the measure of required availability (Service Level). The higher the standard deviation of the forecast and the higher the declarative Service Level, the greater the safety stock.

SAFETY SAVE = z * σ

z – the number of standard deviations needed to achieve the required Service Level

σ – standard deviation of demand in Lead Time period

The solution to this problem is to replace the values of Outliers in the sales history with “normal” values ie. such as sales would most likely have taken if the unusual events had not occurred. This should allow our demand distribution to take the form of a normal distribution and protect us from building excessive levels of safety stock.

Of course, abnormal events will always occur, and if you don’t want to deal with lost sales resulting from too little inventory, you should be able to guard against them. This topic we will try to address in our next episode.

Learn how Smartstock automates the process of managing Outliers. Order a demo.

Ushirogiri technique performed by our school’s iaidō teacher Takashi Kuroki to be viewed on the website: https://www.youtube.com/watch?v=nmgZqhbU8i0

LAST UPDATES

TAGS

- #AI

- #artificial-intelligence-from-A-to-Z

- #bullwhip-effect

- #covid19

- #demand-forecasting

- #forecasting

- #Intelligent-Development-Operational-Program-2014-2020.

- #inventory-management

- #inventory-optimization

- #NCBiR

- #neural-networks

- #out-of-stock

- #outllier

- #overstock

- #safety-stock

- #safety-stock

- #seasonal-stock

- #service-level-suppliers

- #stock-projection

- #stock-projection-over-time

- #supply-chain

- #supplychain

Related entries

How about AI: what is it and how does artificial intelligence work?

READ

Artificial intelligence (AI) is the ability of machines to exhibit human skills such as learning, inference and recommending solutions. Artificial intelligence enables associations to be made […]

The essence of the classic model of inventory renewal based on the information level – the point of reordering

READ

The main feature of the model based on the so-called. “ordering point,” also known as an information-level ordering system or continuous review [3], is a condition […]

Fuzzy systems

READ

Based on fuzzy sets, a fuzzy inference system can be built. In such a system, fuzzy rules are implemented for modeling, which in turn make it possible to carry out the process of fuzzy inference.